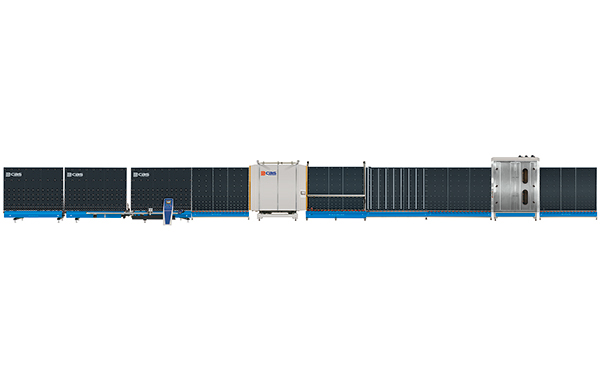

IGL-2210E-SS Automatic insulated glass production line with sealing robot

Features and functions:

1. The production line including glass loading section, washing & drying section, glass transportation section, inspection & spacer assembly section, glass assembly section, plate press section, output section and sealing robot.

2. Automatically distinguish he coating side of coated glass and Low-E glass.

3. PLC controller with touch screen operation.

4. It adopts outside glass assembly, which can produce standard double layer IGU and three layers insulated glass unit.

5. Plate press section adopt gear and chain synchronous devise and driven by hydraulic station. The plate press table also openable for maintenance.

6. Whole line adopt frequency converter to adjust speed, output 800 PCS per shift.

7. Integrated with automatic sealing robot which increased the productivity. Double set sealing extruding system is optional.

8. Inside plate press is optional for step IGU production.

Technical parameter:

|

Processed I.G. unit size |

Min: 300x450mm, Max: 2200x3000mm, |

|

Ways of assembly |

Outside automatic assembly, inside plate press |

|

Power |

3-Phase, 4 wires, 380V 50Hz, 37kW |

|

Air consumption |

800L/min |

|

Washing speed |

2-8m/min |

|

Max. working speed |

45m/min(adjustable according to requirement) |

|

Single glass thickness: |

3-15 mm |

|

Insulating glass unit thickness |

12 ~ 50mm; |

|

Compressed air supply |

0.5-1.0Mpa, 0.8m3/min |

|

Water electrical conductivity |

≦50μS/cm |

|

Ambient temperature |

10℃-30℃, following DIN 40040 |

|

Relative air humidity |

≦75%,following DIN 40040 |

|

Overall dimension |

32250x2300x3200mm |

IGL-2210E-SS Automatic insulated glass production line with sealing robot video